Dual spreaders from 1600 to 3200 litres

Description

The range comprises of the general purpose farm spreader the Powerspread Dairy which will spread all types of slurry and straw yard dung and the Powerspread Pro which is aimed at the large mixed farm and professional user and will spread all types of waste including poultry litter, compost and dry industrial wastes with ease The 2400 and 3200 gallon machines are capable of spreading any solid or liquid and have higher discharge rates due to their wider door/discharge rotor arrangement.

The range comprises of the general purpose farm spreader the Powerspread Dairy which will spread all types of slurry and straw yard dung and the Powerspread Pro which is aimed at the large mixed farm and professional user and will spread all types of waste including poultry litter, compost and dry industrial wastes with ease The 2400 and 3200 gallon machines are capable of spreading any solid or liquid and have higher discharge rates due to their wider door/discharge rotor arrangement.

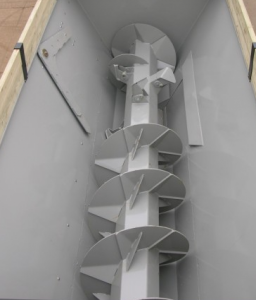

Common design features to all models is the tapered tub design and unique contra rotating auger that pulls dung from both the front and rear of the spreader to the patented centrally opening door.

This produces a ‘boiling’ action inside the spreader when applying a fine coating of manure and reduces the stresses on the body of the spreader. The door of the Powerspread is vertically lifting thus allowing the full width of the impeller to be used at all times, the impeller itself is overshot in design, or spinning upwards, at 700rpm which makes for a very fine fragmentation, which is essential for grassland work, and gives spread widths in excess of 20 metres.

Please choose from the following

- Powerspread Dairy 1600 and 2000

- Powerapread Pro (SWB) 1800 and 2300

- Powerspread Pro (LWB) – 2400 and 3200 gallons

Powerspread Dairy 1600 and 2000

The Powerspread Dairy is the general purpose side discharge farm spreader that will spread all types of slurry and straw yard dung. It has a fixed main auger speed of 13 rpm at 540 PTO speed which makes for fast and efficient spreading. The overshot impeller spins at 700 rpm giving a fine fragmentation to the dung and an even and accurate spread of up to 18metres width.

New dairy rangeThe patented centrally opening door is fed from both ends of the spreader body by means of a contra rotating auger which reduces internal stress in the spreader body and provides a boiling action to further break down the dung inside prior to being spread by the impeller. The door opens vertically allowing use of the full width of the impeller even when applying a very fine amount of slurry or dung.

The drive system is via a heavy duty chain and sprocket system for ease of maintenance and has separate shear bolt protection for both the auger and the impeller. The tapered body design and low central auger gives good stability and the standard 23.1 x 26 tyres ensure minimal compaction.

Powerspread Pro (SWB) 1800 and 2300

The Powerspread Pro SWB (Short Wheelbase) is a side discharge spreader with overshot impellor as found on the Powerspread Dairy but with unique new features.Powerspread pro swb

The Powerspread Pro SWB (Short Wheelbase) is a side discharge spreader with overshot impellor as found on the Powerspread Dairy but with unique new features.Powerspread pro swb

The shortwheelbase pro range replaced the long serving Contractor range in 2011. Both the short and long wheelbase Powerspread Pro’s share the same driveline using 1 3/4 inch heavy duty chain to drive the single speed auger. Shear bolts have been uprated from 6mm on the Contractor to 10mm on the Pro and the drive is generally able to transmit significantly more power which will give greater workrates if required.The drive line also has a reverse drive fitted to help clear any obstructions inside the spreader, this coupled with the hydraulic drop down drip tray and impellor will ensure that any obstructions can be removed quickly and spreading can continue with minimal time loss.

Powerspread Pro (LWB) 2400 and 3200 gallons

Maintenance time is dramatically reduced by the standard fitment of a localised greasing system, this groups grease points that are difficult to access. The Powerspread Pro (SWB) comes as standard on 23.1 26 tyres which are mounted on 40 kmh hydraulically braked axles to match the speeds of modern tractors.

Maintenance time is dramatically reduced by the standard fitment of a localised greasing system, this groups grease points that are difficult to access. The Powerspread Pro (SWB) comes as standard on 23.1 26 tyres which are mounted on 40 kmh hydraulically braked axles to match the speeds of modern tractors.

These features all combine to give the Powerspread Pro (SWB) the ability to give a high work rate with fast and efficient spreading. Two sizes are available in 1800 and 2300 gallons.

The Powerspread Pro range consists of two models the 2400 gallon machine and the 3200 gallon model. The Pro 3200 has a capacity of about 15 tonnes in solid manure– the concept behind its development being to boost capacity and increase discharge rate to bring it in line with the output expected from similarly sized rear discharge spreaders.

While the Pro 3200 is aimed primarily at the contractor and large scale livestock farmer, the more conservative Powerspread 2400 has a capacity of about 11 tonnes and is ideally suited for use by more average size livestock units.

Both models employ a large diameter horizontal auger to convey material to the centrally positioned rotor which then powers it out to the right of the machine to create an even, 20m wide spread pattern. The use of more vertical rather than sloping sides used in previous models, along with an agitator unit eliminates any tendency for material to bridge above the auger as the spreader empties.

Both models employ a large diameter horizontal auger to convey material to the centrally positioned rotor which then powers it out to the right of the machine to create an even, 20m wide spread pattern. The use of more vertical rather than sloping sides used in previous models, along with an agitator unit eliminates any tendency for material to bridge above the auger as the spreader empties.

The rotor, which turns at 750rpm, has an upward rotation and uses the specially strengthened edge of the exit door as a shear bar; material is reduced in size as it leaves the machine and creates an even spread pattern. The door itself has a hydraulically operated slide so that application rates can be controlled from the tractor cab.

Aware that extraneous material such as lengths of wood and large stones, can find their way into a spreader and cause blockages, Shelbourne has built in a raft of protection and clearance systems for the two new spreaders.

The main drive from the pto has a shear bolt protection and two further shear bolts provide over load protection for the rotor and auger drive – both of which employ simple chain and sprocket drive systems. The paddles are attached to the rotor by a single bolt and, as a result, when an obstacle is encountered, rotate backwards to prevent damage.

Should the system experience a blockage, access to the machine is made easy by raising the exit door slide to its full extent and, for the first time, by being able to hydraulically lower the rotor to below floor level so the maximum accessible area becomes available.

A reverse drive facility is also fitted as standard enabling the operator to reverse the central feed auger in the event of a blockage.

For maintenance, a bank of greasing points are placed conveniently at the front of the spreader and supplies grease to all the main bearings. Chain tensioners ensure the two drive chains always run correctly.

For maintenance, a bank of greasing points are placed conveniently at the front of the spreader and supplies grease to all the main bearings. Chain tensioners ensure the two drive chains always run correctly.

An adjustable slurry deflector allows the operator to control the spread distance and height.

Both the Pro 3200 and 2400 models require very little power to operate – the brunt of the power being required to handle the weight of the fully loaded spreaders. As such, Shelbourne Reynolds recommends a minimum of 120hp for the larger spreader.

Running gear comprises 650/65 R 30.5 Trelleborg flotation tyres on a single axle with an option for tandem axles. Options extend to air brakes rather than hydraulic brakes and, for those needing to know precise application rates, weigh cells can be fitted if specified.