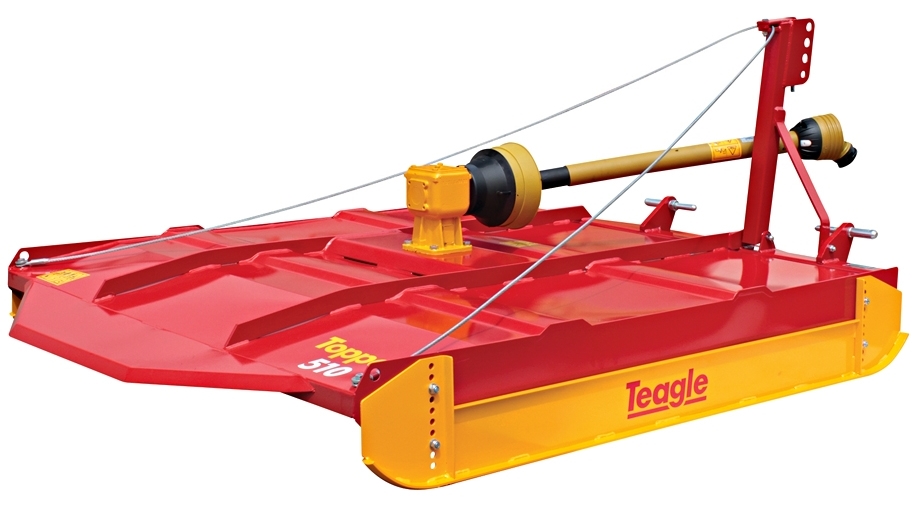

Teagle Toppers available from 4′ to 5′ 10″

- Reinforced rotor

- Easily adjustable cutting height using skids

- Heavy swinging blades

- Hardened Blades – pivoted on hardened bushes

- Rugged construction

- Semi offset

- Flexible top linked post to follow ground conditions

- Good finish from semi offset design. Only one wheel runs on uncut grass. Rotor correctly positioned to cut wheel mark and cut material is evenly spread.

Overview of full range

Available in three cut widths;

- Topper 4 : 1.22m (4′) order only

- Topper 5 : 1.52m (5′) order only

- Topper 510 : 1.78m (5’10”) Stocked

Specification

| Topper 4 | Topper 5 | Topper 510 | |

|---|---|---|---|

| PTO Speed | 540rpm | 540rpm | 540rpm |

| Implement Linkage | Category 1 | Category 1 | Category 1 & 2 |

| Length | 1.88m | 2.08m | 2.40m |

| Cutting Width | 1.22m | 1.52m | 1.78m |

| Overall Width | 1.36m | 1.64m | 1.9m |

| Cutting Height | 12-130mm | 12-130mm | 12-150mm |

| Number of Rotors | 1 | 1 | 1 |

| Weight | 170kg | 213kg | 293kg |

| PTO power required | 10 KW (12 HP) | 15 KW (20 HP) | 19 KW (25 HP) |

| Offset | Central | Central | Semi-Offset |

Reinvigorate productive growth

- Whilst we would like grass to thrive and produce as much plant matter as possible in grazing pastures, we do not want it to go to seed. When this happens, the plant directs it’s energy away from producing the leaf towards growth of the stem and seed itself. This can happen when grass gets away from stock, or more commonly, through patchy grazing.

- Pasture that is going to seed can be recovered and growth reinvigorated by one pass with a Pasture Topper.

Management of Weeds

- By topping weeds prior to them going to seed their spread can be partially controlled, in particular in organic farming situations or on any farm where agrochemical use may be restricted.

Outstanding Performance

- All models incorporate a range of features to ensure ease of operation and maintenance.

British Built Quality

- Our Toppers incorporate high strength pressings and an impressive driveline and blade system resulting in a very robust machine.

- All machines built at our factory in Cornwall are now Shot Blasted and finished with Powder Coat paint for outstanding durability.

Attention to detail

- The hardened spring steel blades pivot on hardened bushes. The blades are cranked to reduce and possibility of stone damage, and to lift the grass as it is cut. The tempered spring steel blade holders provide yet further protection against hidden objects